Molecular sieve absorbs moisture of the compressed air. It can prevent the moisture condensation in…

Molecular sieve absorbs moisture of the compressed air. It can prevent the moisture condensation in the pneumatic brake system and avoid the failure of the system. With high strength and wet attrition resistance the molecular sieves can guarantee the performance and prolong the life cycle of the brake system.

Zeochem offers a wide variety of adsorbents to remove contaminants from hydrocarbon streams in diverse refinery applications. Contaminants such as COS, CS2, H2S, HF, oxygenates, ammonia (NH3) and other nitrogen and sulphur compounds can be removed using Zeochem products in regenerative and non-regenerative adsorption processes. These adsorption processes can include mixed and single bed designs…

The effective dehydration of cracked gases and olefin streams is critical to avoid freezing or the formation of hydrates during cryogenic processing. Molecular sieves are used to remove water and other contaminants such as sulphur in these olefin streams. The diversity of the cracked gas feedstocks and the reactivity of the streams processed present particularly…

For the purification of hydrogen Zeochem recommends the use of a high quality 5A product which is designed specifically to remove CO molecules via a PSA process. This product, Zeochem Z5-01, is successfully in use in numerous hydrogen plants worldwide.

Molecular sieve adsorbents are crystalline alumino-silicates, known as zeolites. Their unique structure allows the water of crystallization to be removed, leaving a porous crystalline structure. These pores or “cages” have a high affinity to re-adsorb water or other polar molecules. Aided by strong ionic forces (electrostatic fields) due to the presence of cations such as…

ZEOflair are highly active zeolites adsorbents in powder form for the removal of undesirable odors, flavors and volatile organic component (VOC). ZEOflair are non-toxic, odourless, micro porous, organophilic inorganic, free flowing and thermal stable white powders with a large adsorption capacity for odors and other volatile organic compounds (VOC) including larger molecules. ZEOflair are used…

Polyurethane can be manufactured either in a single-component or in a two-component system. In both cases, any water still present may react with the isocyanate forming carbon dioxide gas and leading to the formation of bubbles in the final compound. PURMOL® is a hydrophilic molecular sieve powder. It is used to remove moisture from…

As our population grows older and respiratory ailments continue to increase, the need for oxygen-enriched air is on the rise. Many companies are designing and manufacturing medical oxygen concentrators utilizing Zeochem high performance ZEOX® products to allow customers the versatility necessary to live an “active” life. Zeochem’s commitment to develop and produce the highest quality…

High N2 Adsorption and high N2/O2 Selectiviy Product which is Zeochem Z10-04 used in Medical Oxygen industry.

High purity industrial gases such as O2, N2, H2 and CO are manufactured through defined, highly specialized production processes. These processes include essential separation stages, where high quality Zeochem molecular sieves play an indispensible role, worldwide. Cryogenic Air Separation Units (ASU) In order to separate air cryogenically into oxygen and nitrogen the air must be…

VPSA System. Oxygen Plants. For these non-cryogenic O2 plants, Zeochem also offers a variety of adsorbents with high N2 capacity and high N2/O2 selectivity. The latest generation products such as Z10-04, for PSA units, and Z10-05-03, an advanced LiLSX adsorbent for VSA plants, provide customers with improved plant economics.

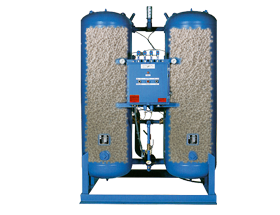

Drying Applications Zeochem is one of the leading manufacturers of molecular sieves for use in drying applications. Zeochem products offer high physical stability (high crush strength and low attrition), excellent adsorption kinetics and high water equilibrium capacity to secure a low dew point. High Capacity Desiccants Zeochem offers high-capacity desiccants in beaded form based on…

Distillation of ethanol is only possible up to the azeotropic point at 95.6% volume. Nowadays the preferred technology for the dehydration of ethanol beyond this azeotropic condition is pressure swing adsorption using synthetic molecular sieves. This dehydration step is necessary for the ethanol to meet the fuel grade standard of >99% or >99.5% ethanol. Other…